Yearly FDA Certification

For companies in the medical and food industries, the FDA requires a regular certification for all their injection molding machines. Generally, this is a calibration verification to certify that the machine is consistent, repeatable, and making the same part time and time again. This is especially important for manufacturers in the medical industry. When you make something like a syringe there can be no deviation. It must be the same syringe each time.

This certification is a blanket certification and depending on the machine and application, is good for anywhere between one and two years.

Why Should I Calibrate My Machine If It’s Not Required?

It’s all about getting in front of your preventative and predictive maintenance and keeping your machine in top condition. A yearly verification goes right along with your quarterly maintenance check. If you keep your machine calibrated and it’s performing at its best, then you drive down your maintenance cost as well as machine down time.

There are also many industries outside of food and medical that require a high degree of consistency and repeatability. For example, automotive manufactures desire the same kind of accuracy, but typically there’s no official certification necessary. A lot of our customers that make automotive parts, however, still ask that we calibrate their machines. Our technicians do many calibrations for customers that don’t require certifications. Overall, having your machine certified or calibrated is like a yearly physical for your machine. It keeps it healthy and producing while reducing maintenance costs and downtime.

How Does Certification or Calibration Work?

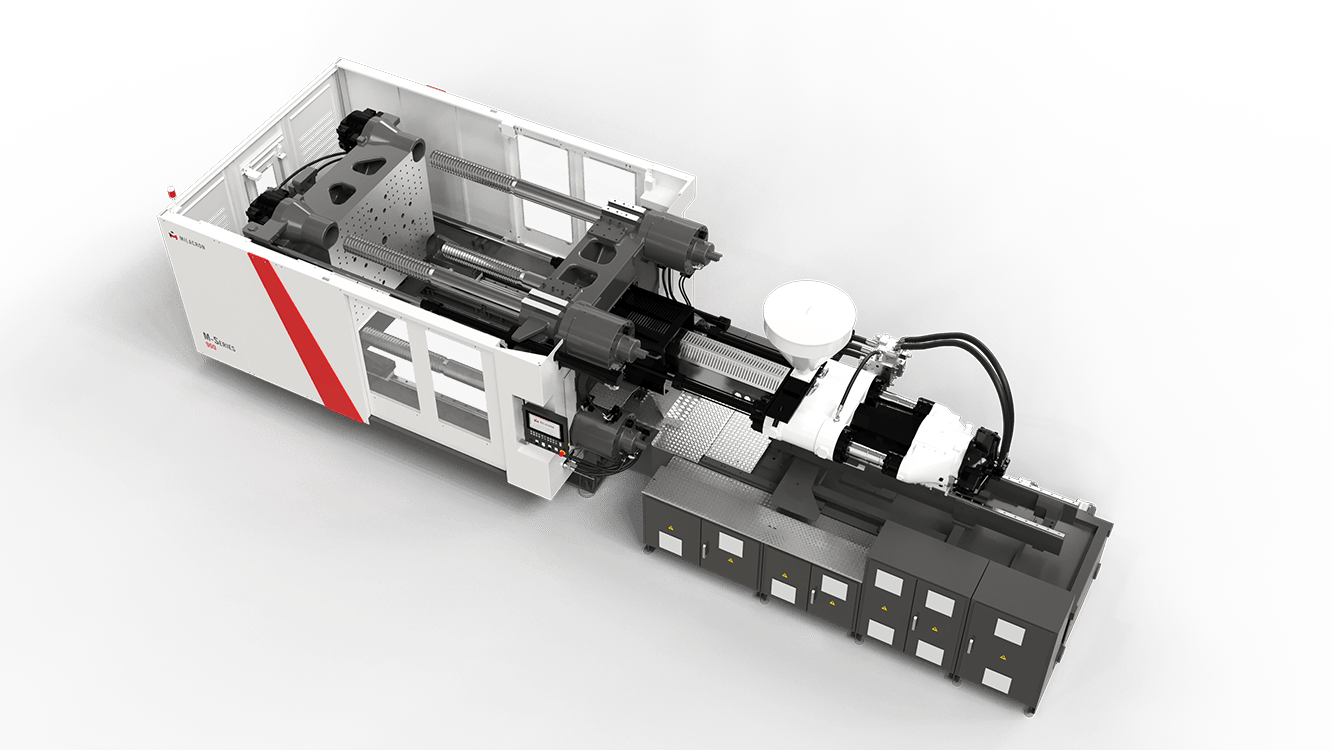

We verify the machine DC power supply voltages, the clamp and eject positions, machine tonnage, mold protect pressures, nozzle and barrel temperatures, oil temperature, injection positions, hydraulic pressures, extruder RPMs, and injection velocity. It’s basically a whole health check of your machine.

Generally, it takes a full day to calibrate or certify your machine. After the process is complete, we give a baseline of recommendations. For instance, if we find that your pump pressures are out of tolerance then we may recommend a service visit.

How can I Get My Machine Calibrated or Certified?

The Milacron Aftermarket Services Team offers a full line of parts and services to assist you in all your preventative and scheduled maintenance needs. Calibration Verification will allow you to stay in front of preventative maintenance issues and ensure that the machine is performing at optimal running conditions.

Call your Regional Service Manager to schedule an appointment today.

Scott Mason

Technical Support and Parts

1-800-288-8306