Press Release

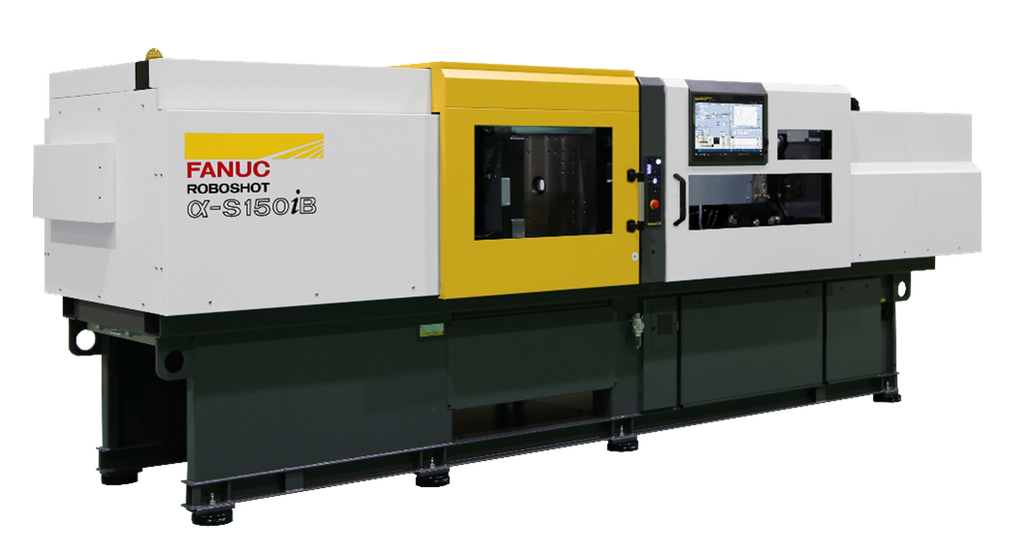

MILACRON EXPANDS ALL-ELECTRIC MACHINE PORTFOLIO: LAUNCHES NEW FANUC ROBOSHOT ALPHA-SIB SERIES

March 30, 2021

Milacron, a leading industrial technology brand serving the global plastics processing industry, announced a new addition to…

Press Release

January 22, 2026

Global plastics leader to showcase advanced machinery, smart automation, and sustainable material innovations February 3-5th at the Anaheim Convention Center in Anaheim, California.

Batavia, Ohio – January 20, 2026 – Milacron®, a global leader in plastics processing technology, will showcase its newest advancements in all-electric injection molding solutions and integrated automation at MD&M West 2026, held February 3-5th, 2026 at the Anaheim Convention Center in Anaheim, California.

Attendees visiting the Sepro-Milacron booth 4601 will experience high‑precision, energy‑efficient, and sustainability‑driven solutions engineered for today’s most demanding medical applications in a compact, all-electric footprint.

“MD&M West continues to be a critical stage for demonstrating how all‑electric injection molding can reshape what’s possible in medical and high‑precision manufacturing,” said Kent Royer, Senior Product Manager at Milacron. “Our FANUC–Milacron Roboshot platform delivers unmatched accuracy, consistency, and energy efficiency—giving customers a smarter, cleaner, and more reliable production platform for their most demanding applications.”

Milacron‑FANUC Roboshot ALPHA‑S110iB demonstrates precision, reliability, and flexibility

Milacron will demonstrate the Roboshot ALPHA‑S110iB, an all‑electric injection molding machine optimized for liquid silicone rubber (LSR) applications in automotive, electrical, and medical markets.

Key capabilities include:

The work cell will produce a medical membrane part, leveraging a 28mm LSR injection package for ultra‑precise dosing—ideal for cleanroom environments. Communications to the Elemet dosing unit, water control and using smart water manifold system provides a system solution.

Collaborating Partners:

FANUC-Milacron Roboshot showcases four decades of collaboration in plastics processing

A culmination of a partnership spanning more than four decades with FANUC Corporation, the Roboshot is Milacron’s most versatile and precise all-electric machine. The platform features the next generation of artificial intelligence (AI) with mold and eject protection and injection molding preventative maintenance features that keep plastics processors running smoothly.

With its 100% electric design, there is no oil, filtration, and disposal to worry about. Roboshot is designed to reduce energy consumption by 50 to 80% while maintaining repeatable and precise cycles that are 5 to 50% faster than hydraulic machines.

Engineered for greater rigidity, Roboshot’s proven performance makes it the perfect solution for cleanrooms and other environments that demand precise process control, high-speed injection, and consistent repeatability.