The plastics processing industry is undergoing unprecedented transformation, driven by evolving customer expectations, technological innovation, and a growing emphasis on sustainability. In today’s competitive environment, plastic processors must pursue higher productivity, lower energy consumption, and greater operational reliability — all without compromising manufacturing goals.

At Milacron, we believe that innovation must be practical, measurable, and future-proof. By combining deep industry expertise with real-world validation, we continue to empower plastic processors to address emerging challenges with greater agility and assurance.

The Challenge: Balancing Efficiency and Productivity

Today, manufacturers face a dual imperative: increasing throughput while minimizing operational costs. Historically, these goals often competed, but advances in machine design, control systems, and intelligent operating modes make it possible to achieve both simultaneously.

With energy costs, machine downtime, and maintenance-related disruptions posing significant operational risks, selecting the right technology platform has become a strategic decision influencing long-term competitiveness and profitability.

A Smarter Approach: Optimizing Efficiency Through Innovation

Recent comparative evaluations highlight how next-generation injection molding solutions deliver tangible improvements across key performance metrics. Real-world validation ensures that technological advancements translate into measurable outcomes on the shop floor.

For example, smart injection molding machines have demonstrated the ability to:

- Achieve up to 20% higher energy efficiency, depending on duty cycle & utilization, significantly reducing power consumption and operating expenses.

- Deliver up to 3% higher productivity, resulting in thousands of additional cycles per year and increased annual throughput.

- Maintain superior clamp stability and minimize vibration, extending machine and component life while enhancing operational consistency.

These advancements reduce the cost per part and contribute to more sustainable manufacturing practices — a priority that continues to gain importance across industries.

Milacron’s Perspective: Setting New Benchmarks in the Small Tonnage Injection Molding Solutions

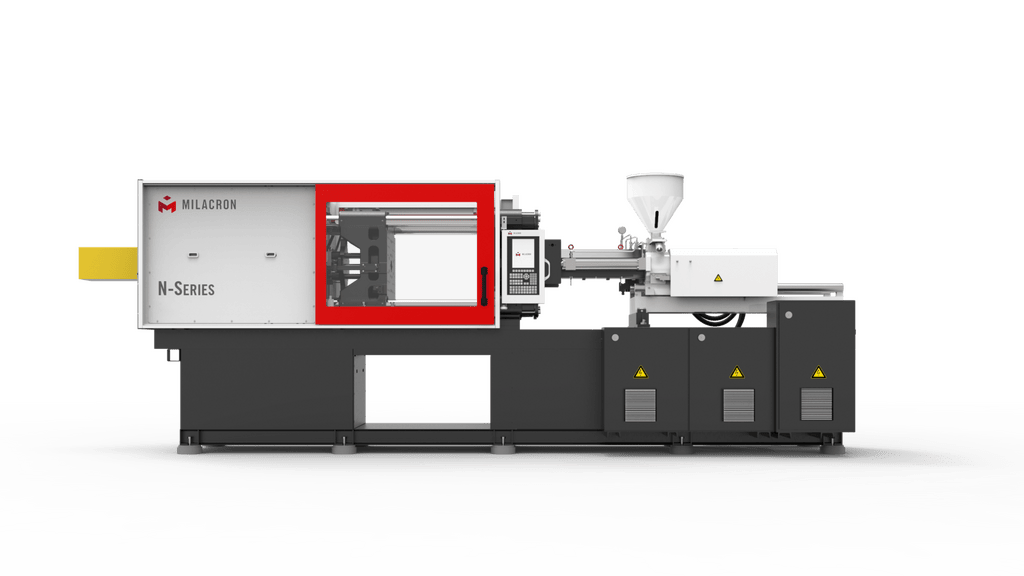

At Milacron, we are committed to engineering solutions that deliver measurable value for plastics processors. Through rigorous head-to-head testing against comparable competitor models, the new N-Series, equipped with the Mode Switch Feature, ranging from 110 to 220 Tons, has set new benchmarks for efficiency, productivity, and reliability.

Operating in Eco Mode*, the N-Series helped achieve the following:

- 8% greater energy efficiency, saving approximately 2,900 kWh annually.

- 3% higher productivity, generating around 46,000 additional cycles per year.

- 50% lower vibration levels, promoting smoother operations and longer equipment life.

By offering flexible operating modes — from Eco Mode* for energy savings to Performance Mode for maximum throughput — the N-Series enables manufacturers to dynamically optimize their production strategies without compromising operational excellence.

Designed to meet the needs of diverse sectors, including Automotive, Packaging, Consumer Goods, Construction, Medical, Electrical, Electronics, and Telecommunication, the N-Series emerges as the new benchmark in small-tonnage injection molding solutions.

*Patent Pending

Conclusion

As the plastics processing industry evolves, the demand for innovative, energy-efficient, and resilient plastic processing solutions will continue accelerating.

At Milacron, we remain dedicated to driving this transformation by blending technological innovation with real-world validation. Through highly engineered solutions like the N-Series, we aim to empower manufacturers to achieve greater operational excellence, enhance sustainability, and confidently lead into the future.

Abstract

Manufacturers are turning to more innovative, data-driven machinery solutions as the plastics processing industry faces increasing demands for efficiency, sustainability, and operational reliability. This article explores how technological advancements enable processors to achieve higher productivity and lower energy consumption without trade-offs. It highlights key industry trends and presents insights from Milacron’s real-world validation of the N-Series 150T, a next-generation injection molding machine engineered for measurable performance gains.

By blending innovation with practical outcomes, Milacron is helping manufacturers navigate evolving challenges and drive transformative success.

Key Takeaways

- Emerging Trends: Technological advancements in injection molding enable plastic processors to achieve higher energy efficiency, improved productivity, and greater operational reliability.

- Real-World Validation: Milacron’s N-Series 150 demonstrated measurable performance advantages, including 8% higher energy efficiency, 3% increased productivity, and 50% lower vibration compared to a comparable competitor model.

- Future-Ready Solutions: By combining flexible operating modes and more innovative design, Milacron empowers manufacturers to optimize production strategies and enhance long-term sustainability in a competitive marketplace.

As one of the leaders of the plastics processing industry, Milacron India made a commendable presence at Plastasia 2025 – a four-day event that brought together pioneers, partners, and professionals from across the polymers sector. Our participation was strategic and substantial, with a dual presence at our own stall space and at our partner’s booth, both powered by our flagship injection molding machines.

Setting the Stage: A Grand Opening and an Insightful Address

The first day of the exhibition commenced with a formal inauguration ceremony, where our esteemed guest, Mr. Santosh Kumar Chhajer, Director, Dev Packaging, cut the ribbon to mark the beginning of an exciting show. This was followed by a keynote address by Mr. Bill Shukla, Managing Director, Milacron India, who emphasized our commitment to transforming plastic processing through innovative solutions.

Meanwhile, visitors were enthralled by our all-electric eQ 280 producing 1000ml containers live, showcasing both efficiency and precision in real-time production.

We recorded an impressive footfall on the first day itself, marking a dynamic beginning to the event and setting the stage for more engaging interactions with industry professionals.

Building Momentum with Engineering Excellence

Keeping the energy intact, we moved on to the next day, engaging with several visitors and talking about our diverse range of solutions. From micro to large-part molding machines, we presented our portfolio of machines suited for various end-market applications.

Our team of sales and service professionals collaborated with subject matter experts to talk about some of our flagship technology, including our low-pressure injection molding solutions.

We also made sure to dedicate a separate section of our booth for M-Powered – our suite of IIoT solutions that runs sophisticated algorithms that utilize real-time machine learning to monitor machine operations.

Sustained Interest, Steady Impact

Day 3 witnessed continued enthusiasm at our booth as we welcomed visitors from all over the country who marveled at our all-electric eQ 280’s lightning-fast injection molding abilities. Our team remained engaged throughout the day at both stalls – ours and our partner’s – delivering expert guidance and addressing technical queries with clarity.

For many visitors, this day served as a valuable opportunity to connect with our team and witness our solutions beyond the initial buzz. This steady momentum was an affirmation towards our position as a trusted plastics processing partner driven by innovation.

Marking A Resounding Success

We brought the last day of the exhibition to a close with enthusiasm and significant impact. Across four days, we recorded over 1500 visitors, fielded numerous enquiries, and secured multiple customer registrations.

From live production of 1000ml food containers to powerful conversations with industry leaders, our presence at Plastasia 2025 underscored our role as a future-ready plastics processing partner.

We also concluded the exhibition on a high note, as we were crowned Best Stall at Plastasia 2025 – a recognition of our immersive, engaging, and technically-driven showcase. This award was a testament to our mindful design and impactful storytelling delivered across our exhibit.

Thank You Note

Driving Growth through Innovation and Operational Excellence

We extend our sincere thanks to every visitor and fellow industry professional who visited us at Plastasia 2025. Your sustained interest, insights, and enthusiasm made our four-day showcase truly memorable.

While the exhibition has come to an end, our collaboration doesn’t stop here. This experience reaffirmed our commitment towards innovation, engineering excellence, and supporting our customers with solutions, technology, and services. We move forward with stronger connections and renewed momentum.

A part-time firefighter, the CNC Mill Machine Operator of 36 years lives life to the fullest!

A community hero and machine operator don’t often go hand-in-hand, but that’s just another day in the life of Milacron’s Matt Williams.

He’s humble, and helpful, and likes a good challenge.

Matt first laid down his Milacron roots at the former Wilmington, Ohio plant in 1988. It wasn’t too far from home and the company seemed to be a good fit for a young man that enjoyed working with his hands.

Today, 36 years later, Matt puts his extensive experience to productive use as a CNC Mill Machine Operator at the company’s Mount Orab, Ohio screw and barrel manufacturing facility located only 10 minutes from the global headquarters.

During his Milacron tenure, Matt has had the opportunity to run various machines. Barrel cell machine operations, and his current machine centers position, rank among his favorite roles to-date in plastics processing manufacturing.

A man that wears many hats in a week’s time, Matt’s service doesn’t end when his day is done at Milacron. Closer to home, he serves as a part-time firefighter for the Washington Court House Fire Department – a role that delivers both passion and purpose. Then finally, he may get the chance to unwind a bit with a hobby he’s grown quite fond of – woodworking.

Matt lives in Washington Court House, Ohio with his wife, and takes great pride in his two grown kids, as well as his role as “grandpa” to three outstanding grandchildren.

————————————————

Thank you, Matt, for your 36 years of service to our organization, as well as for putting your own life on the line for others in the field of public service.

Grinder Operator out of McPherson, Kansas dedicates more than three decades to Milacron!

More than three decades ago, Jeff Unruh was working for a construction company, and a contact at that company introduced him to Milacron. The rest of his career story is exactly that – HIStory!

Upon arriving at Milacron in November of 1992, Jeff spent the first five years in Pre-Inspection, and from there moved into a grinder role. He’s worked on the same machine at the McPherson, Kansas manufacturing operations facility for the last 28 years – truly a subject matter expert grinder!

Family

A native of Topeka, Kansas, Jeff came to McPherson through the construction company that he worked for prior to getting hired on with Milacron. He met his wife of 37 years in McPherson, where they’ve lived ever since raising their three daughters, alongside now three sons-in-law, and three grandchildren.

Hobbies

When he’s not at Milacron grinding away on his favorite machine, Jeff enjoys woodworking and doing projects for his grandchildren. He also enjoys traveling with his wife and vacationing with his daughters and their families.

Thank you, Jeff, for taking a chance on Milacron more than 30 years ago! We couldn’t be more thankful for your expertise, positive attitude, and willingness to serve the plastics processing industry with passion and purpose year-in-and-year-out.

Plastics News

A Prestigious Industry Recognition and a Moment of Pride for Milacron Associates and Partners!

Milacron is proud to be recognized as one of the ‘Best Plastics & Polymers Brands 2025’ by ET Now Polymers and the Times Group—a prestigious acknowledgment of our commitment to innovation, technology, and service excellence in the Indian plastics and polymers industry.

A Legacy of Innovation & Excellence

For decades, Milacron has been more than a brand—it has been a pioneer in shaping the evolution of plastics processing technology. With a strong presence in India and beyond, Milacron India has powered industries with:

✅27,000+ indigenous machines, driving operational excellence

✅Cutting-edge technology that advances plastics manufacturing

✅A relentless commitment to sustainability and innovation

A Recognition That Inspires the Future

This achievement is a shared success—a result of the dedication, expertise, and passion of every Milacron associate. It reinforces our standing as a pioneering force in the industry, pushing the boundaries of what’s possible in plastics processing.

At the felicitation ceremony, our Managing Director, Mr. Bill Shukla, reflected on Milacron’s journey, future aspirations, and the role of innovation in advancing sustainable manufacturing. He also participated in a panel discussion on “Crafting India’s Future: Advancing Innovation, Skill, and Sustainability in Manufacturing,” sharing insights on how technology is shaping the next era of plastics and polymers.

What’s Next?

As we celebrate this milestone, we remain committed to innovation, sustainability, and delivering customer success. This honor is not just a reflection of our past achievements but a motivation to set new benchmarks in the global market.

Here’s to many more milestones ahead!

Anticipated growth acceleration further strengthens Milacron’s position as the largest North American-based original equipment manufacturer of its kind with a dynamic global footprint.

[BATAVIA, OHIO] March 31, 2025 – Bain Capital, a leading private investment firm, today completed the majority investment in Milacron (or the “Company”), a global industrial leader in the manufacture and distribution of highly-engineered injection molding, extrusion solutions, and aftermarket services for the plastics processing market. Bain Capital will partner with Milacron’s current owner, Hillenbrand, Inc. (NYSE: HI), which will remain a significant investor in the business to ensure the Company’s continued growth.

Milacron has built a legacy over the past nearly 60 years that is defined by innovation, expertise, and a deep commitment to serving its 27,000+ customers as well as each of its nearly 2,000 associates worldwide.

“This is an exciting step in the next chapter for Milacron,” said Mac Jones, CEO of Milacron. “We have established a solid foundation of serving plastics processing customers around the globe for more than five decades through innovative technologies, solutions, and service. More focused resources will allow for the continued development of our offering and the ability to respond to our customers’ needs more readily, enhancing their missions and sustaining their continued success.”

The diverse range of industry end-markets serviced by Milacron includes automotive, construction, consumer goods, electronics, medical, telecommunications, packaging, and much more. The original equipment provider of plastics manufacturing solutions is the largest US-owned and globally served of its kind, with regional offices in Asia, Europe, and Latin America.

“This is a pivotal moment in Milacron’s 50-year history—an opportunity to build on its legacy of innovation and service to accelerate growth,” said Matt Evans, Partner at Bain Capital. “Together, we share a vision for long-term success, driven by strategic investments in technology, products, and services that enhance value for customers in the U.S. and around the world. We are excited to partner with the Milacron team to strengthen its foundation and create lasting impact globally.”

Machine shop leader in Ahmedabad, India celebrates 29 years of service!

Praful Pancholi has dedicated an impressive 29 years to Milacron India, joining the team in April of 1996. Through the years he has demonstrated exceptional skill and commitment, progressing through various roles in plant engineering. Today, he leads the machine shop operations, overseeing a talented team of approximately 100 machinists.

Family

Praful is supported by his loving wife, Gayatri, and their son, Varun, who currently resides in Canada. He values spending quality time with his family and cherishes the moments they share.

Personal Growth and Contributions

Praful’s journey at Milacron is a testament to his dedication and hard work. In the past three years, he has taken on increased responsibilities, stepping up to meet the challenges of his role. He has been actively involved in numerous Kaizen initiatives within plant engineering that focus on enhancing safety, productivity, and delivery. His contributions have not only improved operational efficiency but have also played a significant role in our success, leading to several awards that recognize our industry achievements.

Thank you, Praful, for your unwavering dedication and service to Milacron India. Your commitment to excellence and leadership inspires us all, and we are grateful to have you as part of our team!

Machinist celebrates 50 years of service at Milacron’s Southwest Ohio global headquarters.

Five decades of service to Milacron!

Hedge came to Milacron more than 50 years ago after a good friend’s father convinced him to leave his job at Hobart to join him at Milacron. He started as a Press Operator for the 100” drill presses in 1973.

Since then, he’s enjoyed various roles throughout the years from Bar Mill Operator to a Multi-Machine Operator. He admits to preferring third shift but is currently on second shift as a Boring Mill Machinist and still making the most of every day in the plant with lifelong co-workers he calls friends.

Family

Dave’s wife retired from Milacron about eight years ago after 22 years in circuit boards. They have two grown sons, four grandsons, one granddaughter, two great-grandsons, and two great-granddaughters. He loves spending time with the grandkids and great-grandkids!

Hobbies

Hedge uses his personal dump truck to haul gravel throughout his local community for those who need it for their driveways or parking lots. He also enjoys just being outside on his property in Lynchburg, Ohio.

Perspective

I owe everything I have in this life to Milacron. It’s provided well for my family through the years and supported me through some pretty tough times. Milacron has been a great place to work.

Thank you, Dave, for your dedicated service to Milacron. We appreciate you!

Milacron Quality Control Inspector came to the United States seeking a safer life.

Ricardo Ramirez (Ricky), QC Inspector

Milacron Atlanta

Tenure

1997 – Tooling contractor for several years at CanGen

(now Milacron).

2007 – Returned to CanGen as a machinist for 4-5 years in Tooling, and then moved into Quality Control, where he now serves as a QC Inspector.

Family

Married, 3 kids (one daughter, two sons), 2-year-old granddaughter, and a fur baby.

Heritage

Born in South America’s Republic of Columbia, Ricky came to Atlanta, Georgia / USA in 1995 seeking a safer place to live for his family.

Hobbies

Soccer, bowling, ping-pong, and investments

Favorite book/movie

Titantic and The Champion

How did you end up here?

I just stopped in!

What’s your favorite part about your job here at Milacron?

Being able to use my creativity.

How do you unwind at the end of the day?

I work out.

About Milacron Atlanta

The Milacron Atlanta facility manufactures and rebuilds single screws and barrels for injection molding and extrusion machinery through the hard work of our 40+ associates. In 2024 the facility relocated from Chamblee, Georgia (a suburb of Atlanta) to Norcross, Georgia (also a suburb of Atlanta).

In 2015 Canterbury Engineering and Genca, also known as CanGen, a maker of crosshead dies used for extruding tubing and insulated wire, were acquired by Milacron. Since then, the facility has been a critical part of Milacron’s success as an original equipment manufacturer of plastics processing equipment. And, thanks to associates like Ricky, our legacy of 50+ years of technology, innovation and service carries on.

Thank you, Ricky, for your dedicated service to Milacron Atlanta. We appreciate you!