The plastics processing industry is undergoing unprecedented transformation, driven by evolving customer expectations, technological innovation, and a growing emphasis on sustainability. In today’s competitive environment, plastic processors must pursue higher productivity, lower energy consumption, and greater operational reliability — all without compromising manufacturing goals.

At Milacron, we believe that innovation must be practical, measurable, and future-proof. By combining deep industry expertise with real-world validation, we continue to empower plastic processors to address emerging challenges with greater agility and assurance.

The Challenge: Balancing Efficiency and Productivity

Today, manufacturers face a dual imperative: increasing throughput while minimizing operational costs. Historically, these goals often competed, but advances in machine design, control systems, and intelligent operating modes make it possible to achieve both simultaneously.

With energy costs, machine downtime, and maintenance-related disruptions posing significant operational risks, selecting the right technology platform has become a strategic decision influencing long-term competitiveness and profitability.

A Smarter Approach: Optimizing Efficiency Through Innovation

Recent comparative evaluations highlight how next-generation injection molding solutions deliver tangible improvements across key performance metrics. Real-world validation ensures that technological advancements translate into measurable outcomes on the shop floor.

For example, smart injection molding machines have demonstrated the ability to:

- Achieve up to 20% higher energy efficiency, depending on duty cycle & utilization, significantly reducing power consumption and operating expenses.

- Deliver up to 3% higher productivity, resulting in thousands of additional cycles per year and increased annual throughput.

- Maintain superior clamp stability and minimize vibration, extending machine and component life while enhancing operational consistency.

These advancements reduce the cost per part and contribute to more sustainable manufacturing practices — a priority that continues to gain importance across industries.

Milacron’s Perspective: Setting New Benchmarks in the Small Tonnage Injection Molding Solutions

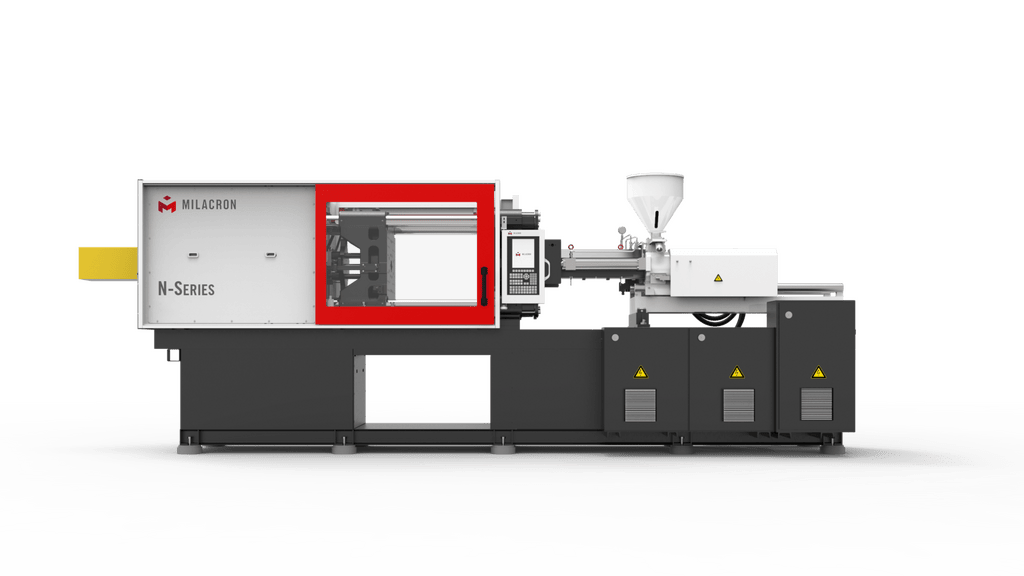

At Milacron, we are committed to engineering solutions that deliver measurable value for plastics processors. Through rigorous head-to-head testing against comparable competitor models, the new N-Series, equipped with the Mode Switch Feature, ranging from 110 to 220 Tons, has set new benchmarks for efficiency, productivity, and reliability.

Operating in Eco Mode*, the N-Series helped achieve the following:

- 8% greater energy efficiency, saving approximately 2,900 kWh annually.

- 3% higher productivity, generating around 46,000 additional cycles per year.

- 50% lower vibration levels, promoting smoother operations and longer equipment life.

By offering flexible operating modes — from Eco Mode* for energy savings to Performance Mode for maximum throughput — the N-Series enables manufacturers to dynamically optimize their production strategies without compromising operational excellence.

Designed to meet the needs of diverse sectors, including Automotive, Packaging, Consumer Goods, Construction, Medical, Electrical, Electronics, and Telecommunication, the N-Series emerges as the new benchmark in small-tonnage injection molding solutions.

*Patent Pending

Conclusion

As the plastics processing industry evolves, the demand for innovative, energy-efficient, and resilient plastic processing solutions will continue accelerating.

At Milacron, we remain dedicated to driving this transformation by blending technological innovation with real-world validation. Through highly engineered solutions like the N-Series, we aim to empower manufacturers to achieve greater operational excellence, enhance sustainability, and confidently lead into the future.

Abstract

Manufacturers are turning to more innovative, data-driven machinery solutions as the plastics processing industry faces increasing demands for efficiency, sustainability, and operational reliability. This article explores how technological advancements enable processors to achieve higher productivity and lower energy consumption without trade-offs. It highlights key industry trends and presents insights from Milacron’s real-world validation of the N-Series 150T, a next-generation injection molding machine engineered for measurable performance gains.

By blending innovation with practical outcomes, Milacron is helping manufacturers navigate evolving challenges and drive transformative success.

Key Takeaways

- Emerging Trends: Technological advancements in injection molding enable plastic processors to achieve higher energy efficiency, improved productivity, and greater operational reliability.

- Real-World Validation: Milacron’s N-Series 150 demonstrated measurable performance advantages, including 8% higher energy efficiency, 3% increased productivity, and 50% lower vibration compared to a comparable competitor model.

- Future-Ready Solutions: By combining flexible operating modes and more innovative design, Milacron empowers manufacturers to optimize production strategies and enhance long-term sustainability in a competitive marketplace.