Milacron, a leading manufacturer in the global plastic technology and processing industry, will leverage its history with Ferromatik to showcase its eQ-Series 110 and eQ-Series 180 electric injection molding machines, as well as its MonoSandWich Technology, at the K 2022 show Oct. 19-26 in Düsseldorf, Germany. Ferromatik, founded in 1956 in Malterdingen near Freiburg, Germany, has been part of Milacron, since 1993.

“Our all-electric injection molding machines have equipped the European plastics industry with groundbreaking multi-component technology since the early 1990s,” said Winfried Stoecklin, Managing Director Ferromatik Milacron Europe. “The K 2022 show is the ideal setting to explore how Milacron’s solutions, technology, service and support can strengthen your operation in today’s competitive landscape.”

Highlights for this year’s show will include:

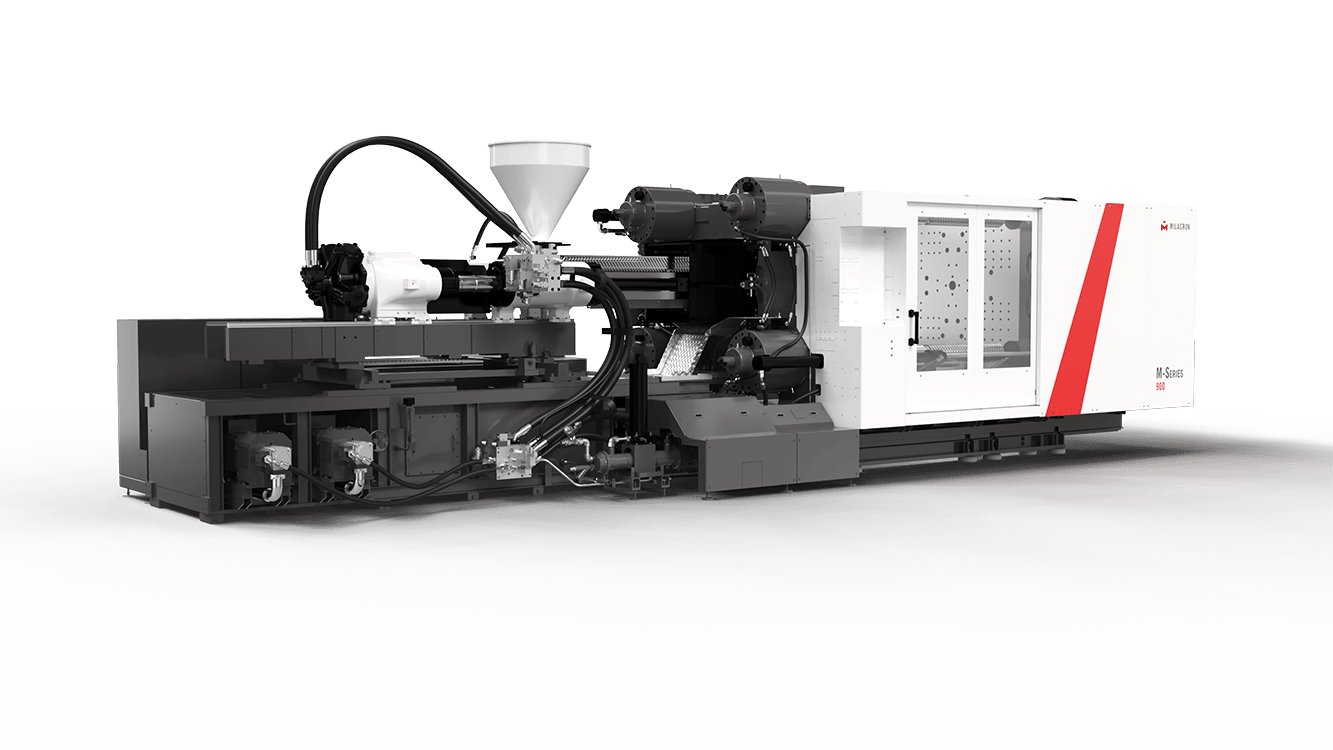

Handle More Applications with eQ-Series 110 and 180 Machines

- Industry leading precise motion, position and pressure control

- Servo driven movements for maximized acceleration, ultimate accuracy and exceptional reliability

- Optimized large tie bar spacing and highly sensitive mold safety

- Superior design with moving platen on L M (Linear Motion) guideway

- Simplified programming of freely configurable cores

- Very low maintenance costs

MonoSandWich Simplifies Multi-Component Molding

- Advanced version of multi-component technology to reduce complexity.

- Significantly reduces manufacturing costs compared to conventional sandwich molding technologies.

Integrations and Demonstrations with Leading Industry Partners

- Milacron integration of iMFLUX software and Auto Viscosity Adjust™ feature on the Milacron eQ-Series machine in the Milacron booth. Demonstrations will feature the iMFLUX “no operator touches” to digitally control the low constant pressure molding technology processing various materials, including 100% PCR. Stop by for a free “Krinkle” bag produced during the demonstrations held daily at 12 p.m., 2 p.m., and 4 p.m. in the Milacron booth, Hall 14, Booth B31

- Milacron eQ-Series 110 machine full integration with a Sepro Group automation cell, producing a small sailboat out of PCR PP, located in the Sepro booth, Hall 12, Booth A49.

“Integrating technologies that support automation is essential for addressing current industry labor trends,” said Mac Jones, President of Milacron. “Our partnerships with iMFLUX, who is transforming the future of plastic injection molding, and Sepro Group, one of the largest suppliers of robotics in the world, demonstrates Milacron’s commitment to solving problems in order to meet the demands of today’s plastics processing.”

In addition to delivering advanced technologies, Milacron is expanding the expert resources available in Europe.

“In order to better serve our growing customer base, we are investing in additional resources to optimize our sales and service team in Europe. The team can deliver the entire spectrum of services — offering expertise in injection, co-injection, extrusion, low-pressure injection molding, process control and asset life-cycle management,” said Peter Kochs, Director Sales and Business Development Milacron Europe.

To learn more about Milacron solutions, technologies and services, please visit the Milacron booth, Hall 14, Booth B31 in at the Messe Düsseldorf in Düsseldorf, Germany.

About Milacron

Milacron, Cincinnati, OH, USA, is a global leader in the manufacture, distribution and service of highly engineered and customized systems within the $27 billion plastic technology and processing industry. It is the only global company with a full-line product portfolio that includes injection-molding and extrusion equipment. Milacron maintains strong market positions across these products, as well as leading positions in process-control systems, and maintenance, repair and operating (MRO) supplies for plastic processing equipment. Milacron’s strategy is to deliver highly customized equipment, components and service to its customers throughout the lifecycle of their plastic processing technology systems. Milacron serves a diverse range of industries and has long-standing relationships with more than 27,000 customers and leading market shares in North America and in many emerging markets, including China and India. To learn more about Milacron and its complete portfolio of injection-molding and extrusion machines and systems, please visit www.milacron.com

Milacron is an Operating Company of Hillenbrand (NYSE: HI), an industrial company operating in over 40 countries serving a wide variety of industries across the world. www.hillenbrand.com

About iMFLUX

iMFLUX, a wholly owned subsidiary of Procter & Gamble, is a software and engineering innovation company that partners with leaders in the plastics industry to enable injection molding customers to deliver significant, sustainable competitive advantage in their market segments.

www.imflux.com/about-imflux

About Sepro Group

Sepro Group has grown with the plastics industry to become a leader in the automation of injection-molding processes. Across its almost 50-year history, Sepro Group has equipped over 40,000 plastic injection-molding machines worldwide.

Discover the leader in robots dedicated to plastic injection – Sepro Group | Sepro Group (sepro-group.com)