Milacron designs and builds full extrusion systems in-house, allowing us to meet your precise equipment needs.

Our demonstration and development laboratories excel at developing solutions for our customers. This creates a highly customizable approach for our customers that helps increase productivity, output, and accuracy towards reducing costs. Our single and twin screw extrusion machines excel in producing sheet, pellets, pipe, window profiles, vinyl siding, and profiles of wood and natural fiber plastic composites. We can also help with challenging projects that require complex system solutions for thermal sensitive compounds, complex shapes, or precision extrusions. Milacron's modular extruder designs offer flexible and reliable solutions that meet your unique needs. Our experienced engineers work with you to design solutions that optimize your production. More than machines, Milacron is a your partner in plastics.

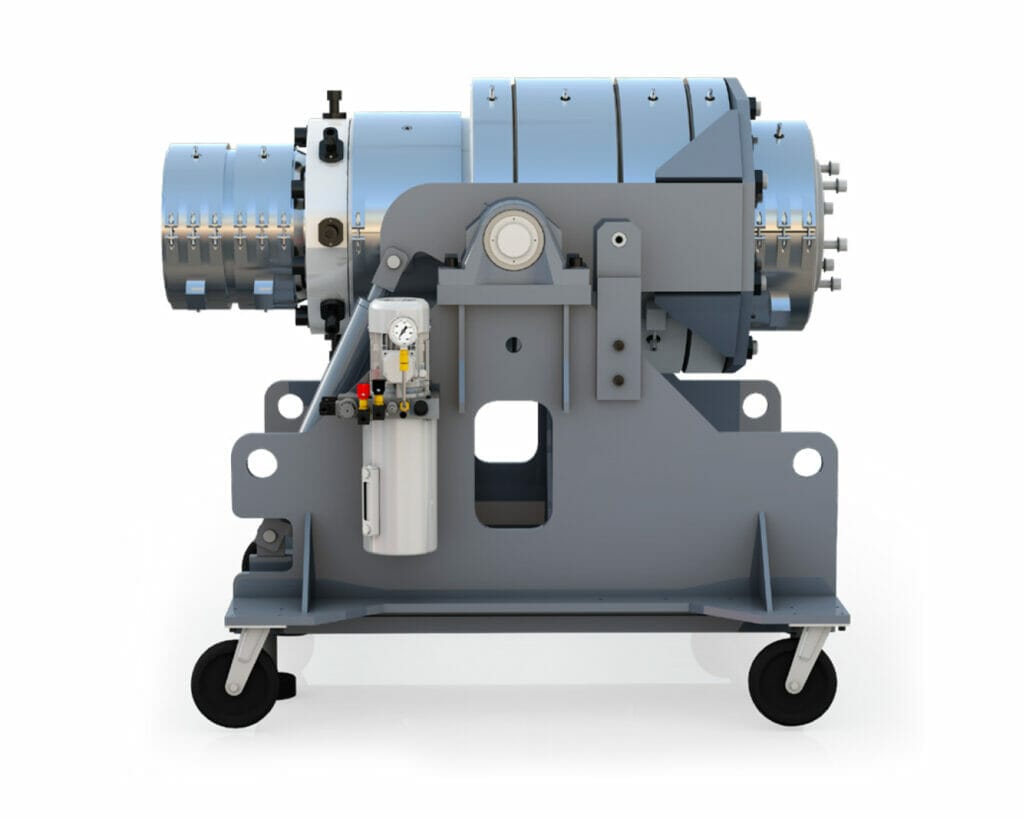

Die Heads

Whether you need a new design or an OEM replacement, Milacron delivers exceptional quality and precision craftsmanship in every die head we manufacture.

Single Screw

Milacron Single Screw Extruders help bring versatility, lower production costs, and ultimately, exceptional value.

Twin Screw

Available in twin conical (TC) or twin parallel (TP) screw configurations, Milacron Twin Screw Extruders are quality built for reliable, long-term operation.

Your Partner In Plastic Processing

Milacron transforms plastics into possibilities.

Contact us today to learn more about our complete plastic processing solutions.