High Performance Injection Molding Machines

Milacron's industry-leading injection molding machines are engineered for performance and versatility. We offer all-electric, servo-hydraulic, or low pressure injection systems with a full range of plastics-processing technologies, including multi-component and co-injection. From 17 to 7,650-ton clamp capacities, our machines are capable of producing everything from precise medical components to large structural plastic products. Built to purpose, our experienced engineers work with you to develop machines designed to optimize your process, decrease downtime, and increase production. More than machines, Milacron is your partner in plastics.

All Electric

eQ-Series

ONLY AVAILABLE IN EUROPE & ASIA. The next generation of injection molding machines, the eQ-Series offers higher precision and more reliable molding capabilities than ever before.

50-650 Metric

Roboshot

ONLY AVAILABLE IN NORTH & SOUTH AMERICA. Our most versatile and precise all-electric machine, the Roboshot features industry-leading artificial intelligence (AI) designed to keep plastics processors running smoothly.

17-500 US

Servo Hydraulic

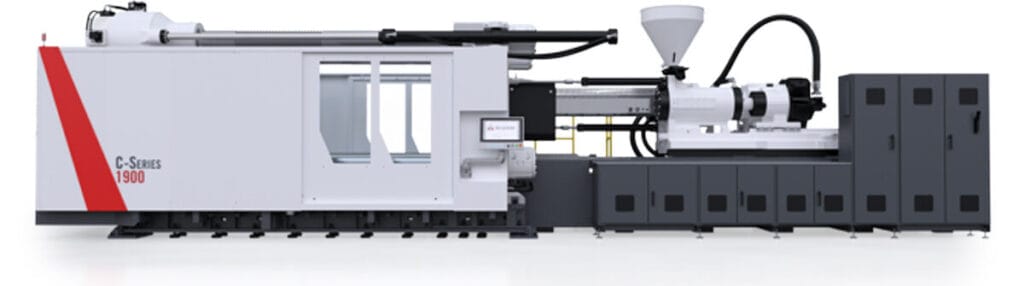

C-Series

A large-part powerhouse, the C-Series enhanced machine specifications offer improved reliability, higher max mold weights, and faster clamp speeds.

1500-4500 US

1300-4000 Metric

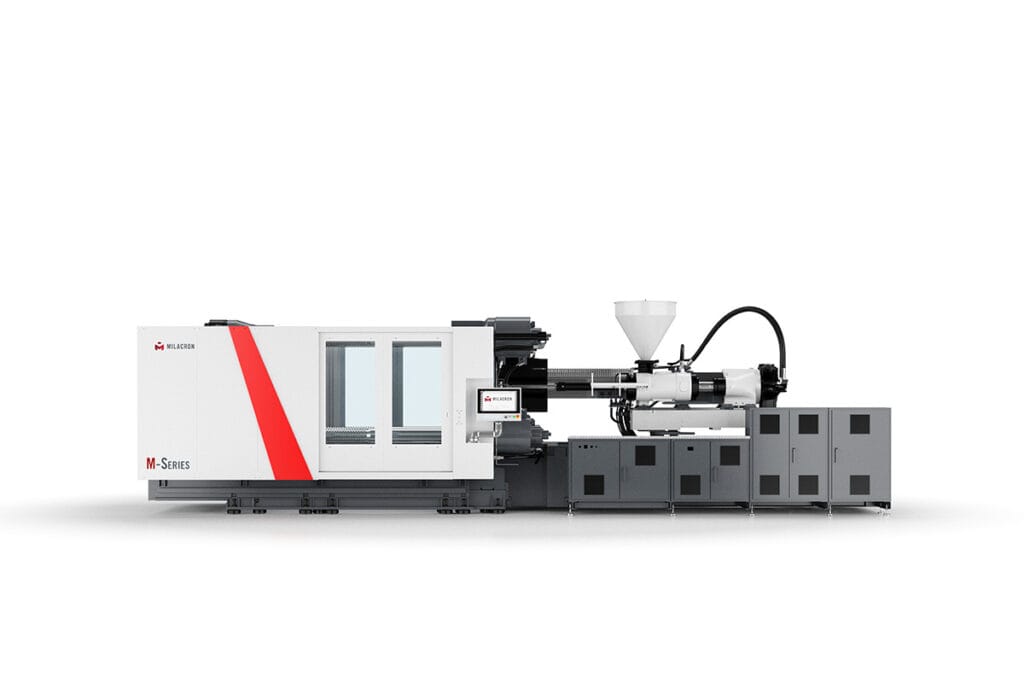

M-Series

High performance, precision, and flexibility in a reduced overall footprint contributes to better floor space utilization and improved access to the molding area.

600-1250 US

550-1100 Metric

Q-Series

A high-performance machine in a durable package, the double toggle Q-Series delivers some of the best quality parts at a rapid pace while minimizing energy use.

55-610 US

Your Partner In Plastic Processing

Milacron transforms plastics into possibilities.

Contact us today to learn more about our complete plastic processing solutions.